The future of how things are made

Large masses of plastic refuse and other marine debris, drawn together by waves and wind, currently float across the north Pacific Ocean between California and Hawaii. Popularly known as the "Great Pacific Garbage Patch," the seafaring pile of trash stands as testament to society’s overreliance on petroleum-based plastics and other materials developed to deliver single-use products quickly and cheaply.

The costs, however, have been immense.

Viable new alternatives to petroleum-based plastics are possible, but they require new materials and new approaches to production and manufacturing.

Recently, the U.S. National Science Foundation asked researchers to reimagine the future of how things are made, laying the groundwork for manufacturing that is sustainable; takes full advantage of artificial intelligence; incorporates advancements in fields such as bioengineering and materials science; and has at its heart, a trained, diverse workforce that can direct fresh ideas and perspectives to address research and production challenges as they arise.

Building a future for manufacturing

NSF currently invests $250 million per year in advanced manufacturing research. From advances in computer-aided design to driving development of 3D printing and sustained advanced nanomaterials, NSF’s decades-long investment in fundamental research has transformed manufacturing, resulting in products modern society has come to depend on.

Recently, NSF made awards to 24 projects in future manufacturing that will build upon this legacy and develop approaches that will impact society just as profoundly for years and decades to come. Bringing together partners throughout the United States, each project pursues breakthroughs across one of three primary areas: eco-manufacturing, biomanufacturing and cybermanufacturing.

This research is not intended to simply improve current manufacturing processes. Instead, the goal is to drive the creation of entirely new methods and means of manufacturing that do not exist today or expand the capabilities behind existing processes that promise success but for now are conducted at too small a scale to be commercially viable. The formation of new manufacturing processes and industries will also create new jobs and opportunities that will bolster economic growth and benefit society at large.

The first steps forward

Eco-manufacturing research addresses issues around product life cycle and develops new approaches that address materials waste during manufacturing, as well as product end-of-life issues across areas such as electronics, building materials and batteries. By looking at the basic elements used in production, new materials can be developed that are more easily recycled and reused, reducing the overall impact on the environment. For example, one project will investigate engineered microbes that could help transition society to greater use of biodegradable plastics. A separate project will look at producing 3D parts and components using materials that can be recycled indefinitely. Both of these approaches could stop another situation like the Great Pacific Garbage Patch from occurring again.

Biomanufacturing research brings futuristic visions of advanced medicine -- such as targeted treatments for diseases and replaceable organs -- closer to reality. By expanding fundamental knowledge in biology and engineering, cells could be used as microscopic manufacturing centers. For example, one project will work to enable future mass production of cell-made particles that could result in a new class of more effective drug treatments. Other research projects will explore ways to expand cell-based manufacturing beyond health care and into areas such as construction materials and electronics.

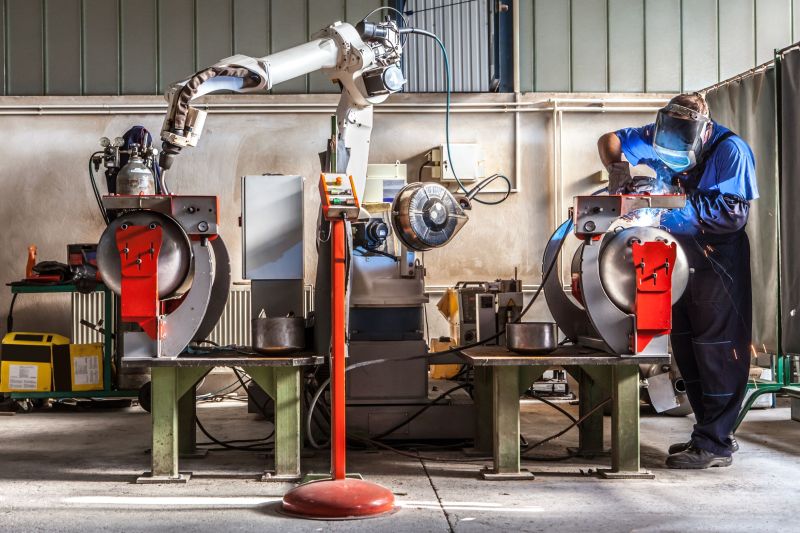

Cybermanufacturing research reinvents the factory paradigm and provides new and expanded opportunities across the United States. By leveraging advanced services, such as cloud computing, data analytics and artificial intelligence, the time and expertise needed to set up and access production lines can be reduced. The creation of multiple small reconfigurable factories that can be located anywhere expands the availability of cost-effective manufacturing to a larger and more diverse group of entrepreneurs. Investigations into modular construction technologies and swarm approaches to manufacturing are some of the first steps in making this happen.

Research in all three areas will also begin to define the roles and opportunities for the next generation of workers in a future manufacturing environment that incorporates increased use of artificial intelligence, robots and biotechnology.

As research advances, manufacturing innovation continues to transform how we live and work and accelerate technological innovation at even greater speeds. Manufacturing leadership has been one of the defining characteristics of the American way of life for centuries, and as sustainability and other challenges continue to emerge, advances in eco-manufacturing, biomanufacturing, and cybermanufacturing will help the nation lead with solutions.