Following in the Footsteps of Nature

Nanotechnology has not only brought nature and engineering closer together; it has encouraged collaboration among researchers of different disciplines. In one such collaboration, two researchers drew on the extraordinary stickiness of a gecko's foot to develop a synthetic adhesive to help robots scale walls.

NSF-funded researchers Mark Cutkosky, an engineer at Stanford University, and Kellar Autumn, a biologist at Lewis and Clark College, have collaborated to develop a gecko-like synthetic adhesive that functions like real gecko bristles for climbing applications. The team discovered the fundamental physics principles underlying gecko adhesion, which enabled the invention of an adhesive nanostructure.

The Tokay gecko, one of the largest and heaviest geckos, served as inspiration.

"The challenge was simply to get robots to go where robots have never been able to go before, like up walls of buildings," said Cutkosky. "If robots can climb vertical surfaces, then they can do inspection of buildings and bridges and other hard- to-reach places."

Cutkosky received a four-year, $1 million National Science Foundation research grant that funded the development of the first gecko-like synthetic adhesive (GSA) that works like real gecko bristles. Autumn received two NSF grants for continued research on gecko adhesion. Cutkosky's team collaborated with Kellar Autumn and his gecko lab to determine whether a synthetic adhesive could be applied to robots.

"The collaboration with Mark's group has been incredibly productive. Based on micro-force measurements, we hypothesized that a coupling of shear force and adhesion was responsible for control of the geckos' attachment system," said Autumn.

A gecko's foot possesses a sophisticated adhesion system that uses van der Waals forces, which are the basic molecular attraction that exists between molecules. Van der Waals forces allow geckos to climb and hang on a smooth and vertical surfaces using one toe.

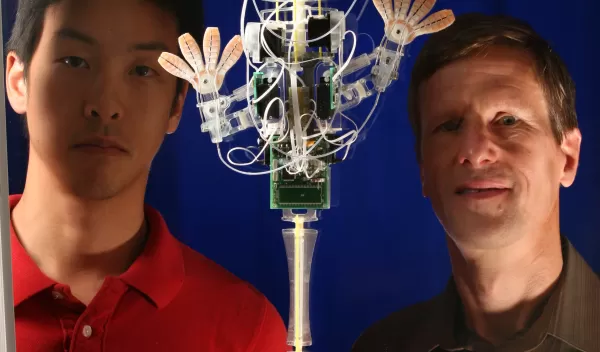

Cutkosky and his team have been designing bio-inspired robots which use van der Waals forces. Their most recent design is stickybot, a robot that has gecko-like pads, which allows it to scale walls and buildings.

Bio-inspired design on a nano scale

The intricate work of nature occurs on a tiny scale, below the limits of our vision. Beneath the surface of a gecko's foot is a three-level hierarchy of structures. The first level is made up of lamellae, which are a series of structures that look like flaps under a microscope. Then, the lamellae are divided into smaller structures called seate which are thinner than a human hair. Finally, the seate branch into tiny little ends called spatulae, which are only a couple of hundred nanometers in size.

"So what happens is that the gecko is able to conform to surfaces ranging from tens or hundreds of nanometers all the way up to centimeters," said Cutkosky. "It is very cool; it is sort of the poster child for complex hierarchical geometry, almost fractal in its nature."

The structures that compose the different levels in the hierarchy have a similar behavior at multiple length scales.

The gecko's toe structures are only adhesive when loaded in a particular direction and the gecko can control adhesion by aligning its microstructures and making intimate contact with the surface. Stickybot follows the same principles as a gecko, but needs to adjust the orientation of its feet as it climbs. This is to ensure that the toes are always loaded in the proper direction for adhesion.

Cutkosky and Autumn have built similar synthetic structures that follow the design of a gecko's foot. At present, they have created a two layer hierarchy of polymers with directional adhesion. This is good enough for stickybot to use to scale walls; however there is always room for improvement.

"It comes down to how much adhesion you are getting per unit area. The gecko can easily support its weight on one toe. In fact, it has lots to spare. Without the latest and greatest adhesives, I think stickybot can barely support its weight on one toe. We are nowhere near the gecko. Basically, it comes down to the weight of the robot and how many pascals of adhesion you can get from your material," said Cutkosky.

The pascal is a measurement of force per unit area which allows researchers, like Cutkosky, to determine how much stress the synthetic adhesion can tolerate. This helps gauge how the adhesive is developed and how it can be changed in the future.

The future of stickybot

Stickybot employs three main principles to climb smooth surfaces: hierarchical compliance to conform to levels from micrometers to centimeters, directional adhesion to smoothly engage and disengage from a surface, and force control to control frictional forces in the feet. Though stickybot can climb on vertical and smooth surfaces, Cutkosky hopes to develop a robot capable of climbing a wide variety of surfaces.

"We are continuing to try and improve the dry adhesive itself, but independent from that; we are working on a new stickybot. Making the ankles of the robot rotate is probably number one, but we also want to do more sensing and control. Right now stickybot doesn't have many sensors, so if it's climbing and starting to get into trouble, it doesn't know that and may fall," said Cutkosky.

Cutkosky and Autumn's research and collaboration have shown how materials science is attempting to follow nature.

"Nature has a huge advantage it can grow and differentiate cell by cell. Whereas, when we manufacture things we're always using processes that work top-down and so every layer is difficult and expensive for us," said Cutkosky.