Engineers discover new process for synthetic material growth, enabling soft robots that grow like plants

A team of University of Minnesota Twin Cities scientists and engineers has developed a first-of-its-kind, plant-inspired process that enables synthetic material growth. The new approach will allow researchers to build better soft robots that can navigate hard-to-reach places, complicated terrain and, potentially, areas within the human body.

The research was funded by the U.S. National Science Foundation and is published in Proceedings of the National Academy of Sciences.

"This is the first time these concepts have been fundamentally demonstrated," said Chris Ellison, a lead author of the paper. "Robots are being used more and more in dangerous, remote environments, and these are the kinds of areas where this work could have an impact."

Soft robotics is an emerging field where robots are made of soft, pliable materials as opposed to rigid ones. Soft-growing robots can create new material and "grow" as they move. Current soft-growing robots drag a trail of solid material behind them and use heat or pressure to transform that material into a more permanent structure. However, the trail of solid material becomes more difficult to pull around bends and turns, making it hard for the robots to navigate terrain with obstacles or winding paths.

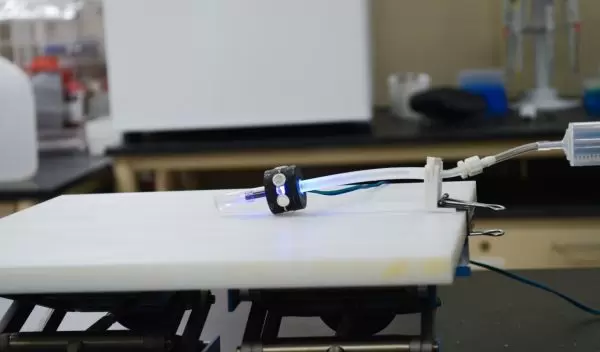

The researchers solved this problem by developing a new means of extrusion, a process where material is pushed through an opening to create a specific shape. That allows the robot to create its synthetic material from a liquid instead of a solid.

"We were really inspired by how plants and fungi grow," said Matthew Hausladen, first author of the paper. "We took the idea that plants and fungi add material at the end of their bodies, either at their root tips or at their new shoots, and we translated that to an engineering system."

This new process also has applications in manufacturing and biomedicine.

"This process, and the innovative soft robots it makes possible, arise from an open-minded and productive collaboration across disciplinary boundaries," said Jordan Berg, a program director in NSF's Directorate for Engineering. "The result is due to a match of expertise in polymer fabrication, mechanical design, biological inspiration and robotics, enabling the team to overcome obstacles hindering the emergence of a revolutionary new class of robots."